expander body

WHAT IS THE EXPANDER BODY

Similar to a steel balloon, the Expander Body is a collapsible steel device installed at the base of piles or anchors. Through controlled grout injection, the device expands to create a bulbous base, effectively compacting surrounding soil. This can increase toe diameter up to 1.2 m and enhance toe resistance by up to 400%. It’s flexibility makes it ideal for piles, micropiles and anchors of buildings, retaining walls, high voltage towers, tunnels, bridges, and more

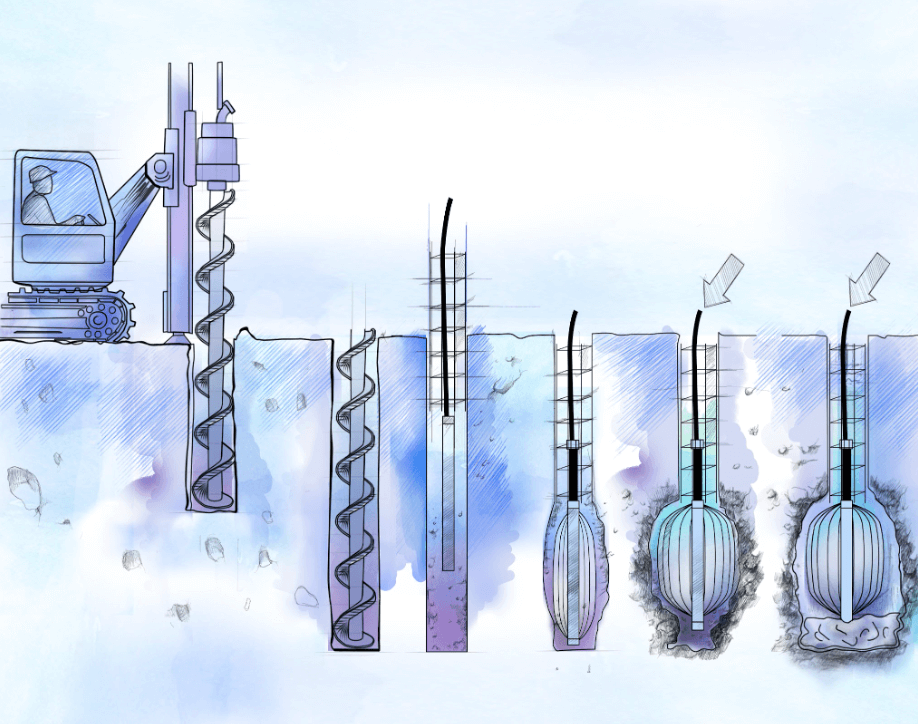

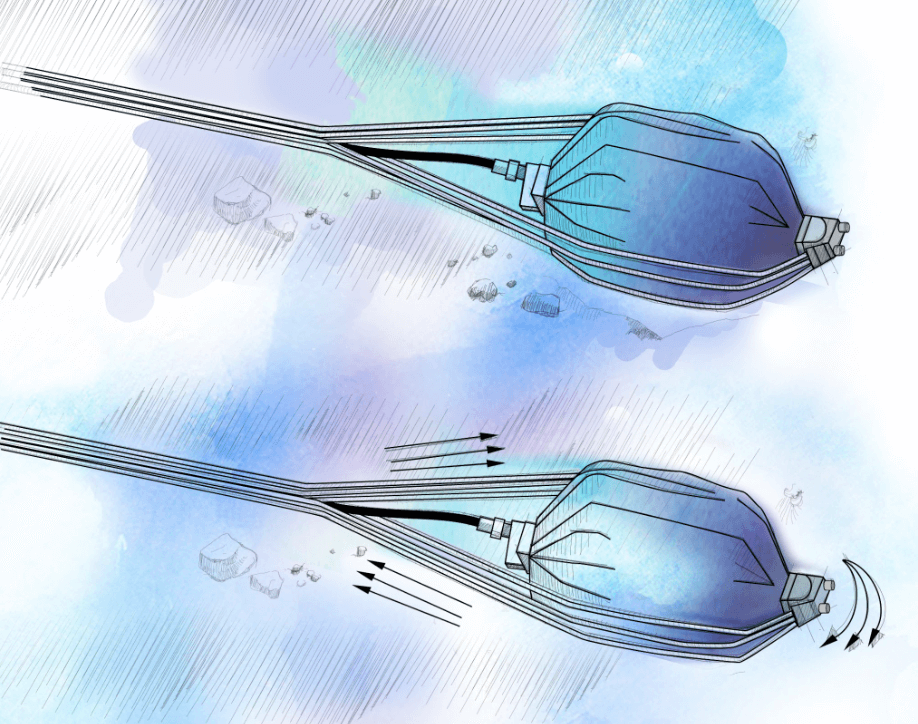

HOW IT WORKS

In general the installation steps go as follow. Depending on the availability of the tools, some steps can be avoided:

Drilling

Using available drilling method (CFA, Kelly, DTH, FDP, Driving, etc) reach desired depth

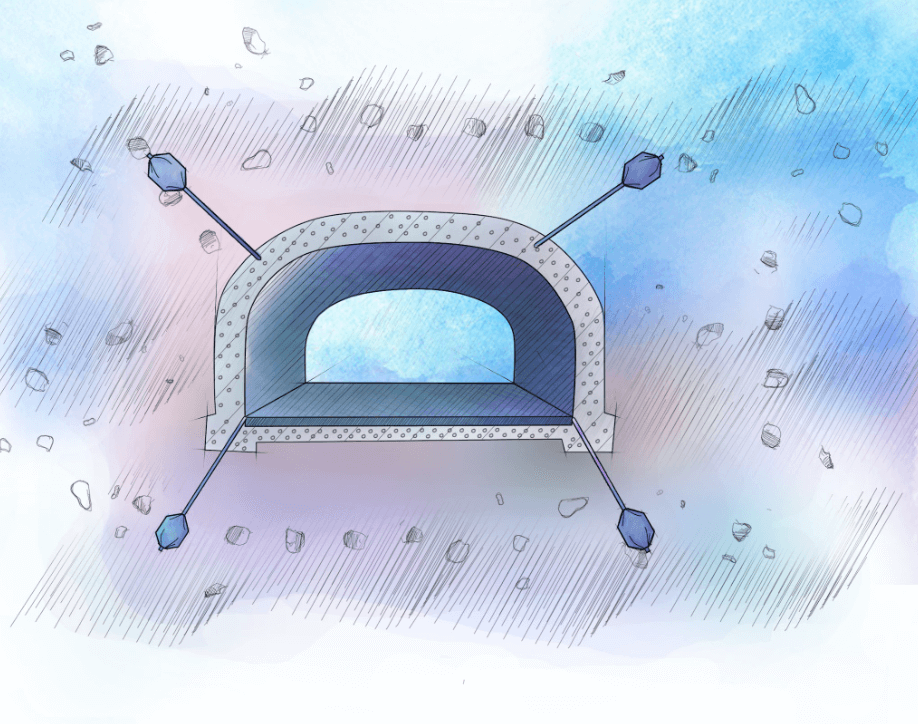

Installation of EB

EB is placed at the desired depth together with reinforcement steel (rebar, solid or hollow bars, pipes, cables).

Concreting Element

Entire shaft length is concreted.

Expansion of EB

EB is pressure-grouted to target volume while monitoring pressure, reaching the maximum expanded diameter of the unit.

Post-Grouting

Additional grout can be injected beneath the EB to further increase compress the soil (for piles and micropiles).

KEY BENEFITS OF EXPANDER BODY

Enhanced Load-Bearing Capacity:

Enhanced Load-Bearing Capacity: Increases the load-bearing efficiency of each pile or anchor by 200–300%, optimizing structural performance.

Reduction in the Number of Piles:

Achieves a 35–60% reduction in the total pile count required, leading to cost and material savings.

Shorter Pile Lengths:

Reduces drilling depth requirements by 30–70%, saving time and resources.

Cost Savings:

Lowers construction costs by 30–65%, thanks to optimized design and reduced material and labor needs.

Real-Time Quality Control:

Provides immediate monitoring of grout pressure and volume during installation, ensuring precision and reliability.

Reduced Carbon Footprint:

Minimizes environmental impact with less material usage, reduced machinery requirements, and up to 50% lower CO2 emissions per project.

KEY FEATURES OF EXPANDER BODY

High Versatility in Installation:

Compatible with various drilling methods, including slurry drilling, Continuous Flight Auger (CFA), Full Displacement Piles (FDP), cased drilling, and driven piles.

Real-Time Monitoring:

Records grout pressure and volume during expansion, immediate QC/QA.

Acts as a Pressuremeter:

Functions as a soil testing device during installation, providing data on soil stiffness and strength.

CASE STUDIES

Explore the diverse range of projects where our technologies have made a difference. From large-scale infrastructure to specialized foundation challenges, our work demonstrates how innovative engineering solutions like Expander Body enhance performance, optimize load capacity, and reduce environmental impact across various geotechnical conditions.

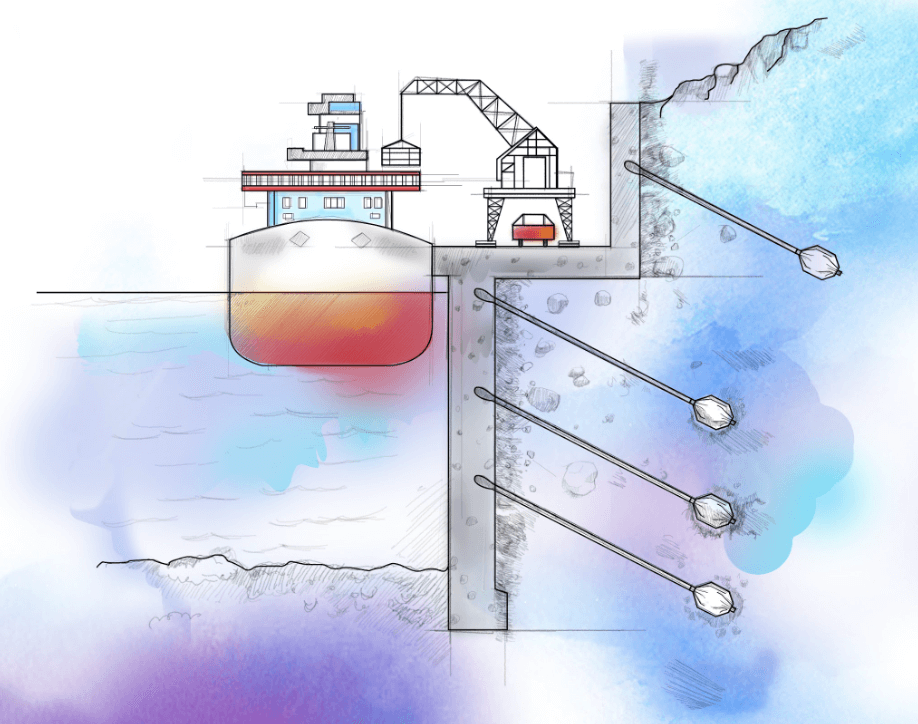

ANCHORS FOR 60KM OF THE 500KV – ARGENTINA.

YEAR: 2005

Number of anchors: 150

- Length of Tiebacks: 9 m.

- Diameter of The Shaft: 0.15 m.

- EB Diameter: 600 mm.

- Service Load: 550 KN

SAVINGS

- Cost: 60%

- Time: 50%

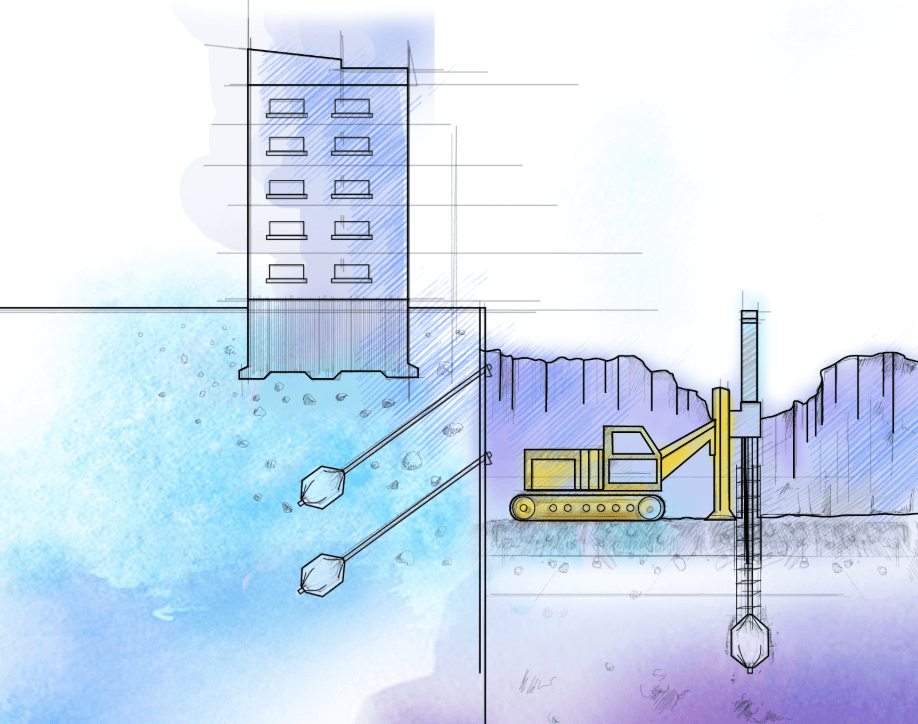

underpinning – united states

year: 2021

Number of anchors: 124

- Length of Tiebacks: 9 m.

- Diameter of The Shaft: 0.18 m.

- EB Diameter: 600 mm.

- Service Load: 900 KN

SAVINGS

- Cost: 40%

- Time: 50%

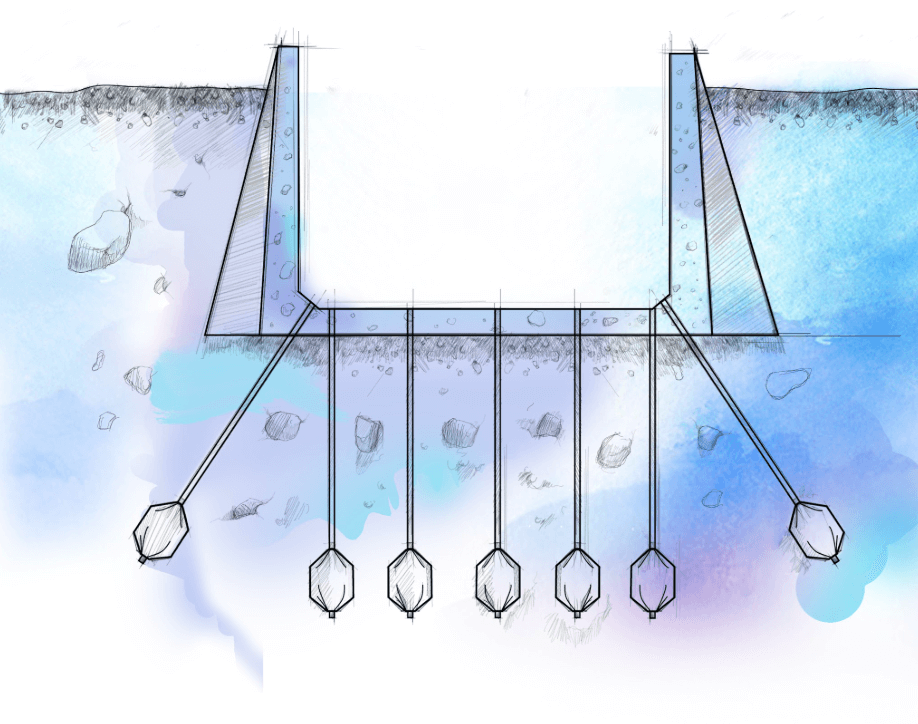

MICROPILES FOR WAREHOUSE – BRAZIL

YEAR: 2021

NUMBER OF PILES: 735

- Length of Tiebacks: 9 m – 11 m.

- Diameter of The Shaft: 0.20 m.

- EB Diameter: 600 mm.

- Service Load: 1300 KN

SAVINGS

- Cost: 45%

- Time: 55%